Vacuum Casting Process

Vacuum Casting Introduction

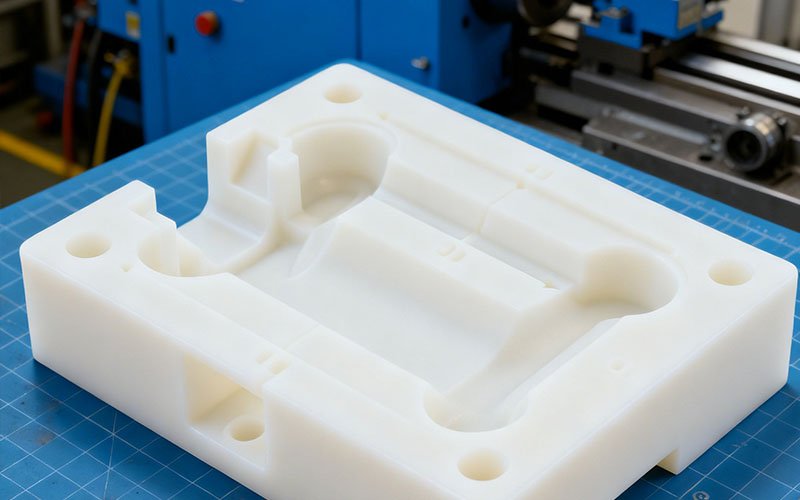

Vacuum casting (VC) is a rapid prototyping and small-batch production technology that uses a vacuum environment to inject liquid polyurethane (PU) resin into a silicone mold, replicating the structure of a finished product identical to the prototype (such as a 3D printed part or a CNC machined part).

This process combines prototyping accuracy with production flexibility, and is widely used in industrial design verification, functional testing, and small-batch product delivery. It is particularly suitable for the rapid deployment of tool kit components, precision hardware accessories, and electronic housings.

Vacuum Casting Process

The core of vacuum casting is to achieve precise filling and bubble-free molding of liquid resin through a vacuum negative pressure environment. The process needs to take into account precision control, efficiency optimization and the small-batch delivery requirements of foreign trade orders.

Suijin Machinery provides standard process flows for large-scale industrial production, while also offering optimized solutions for small-batch customization.

Step 1: Precision Master Model Fabrication

Core Objective:

Provide a high-precision, high-surface-quality prototype (master model), directly determining the accuracy of the replica.

Prototype Fabrication Method:

Preferably use SLA/DLP 3D printing (accuracy ±0.05mm) or CNC machining (suitable for metal/hard material prototypes).

Prototype Pre-treatment:

- 1. Grinding and Polishing: Use 400~1200 grit sandpaper to gradually grind the surface until the roughness Ra≤0.8μm;

- 2. Defect Repair: Fill gaps and air bubbles with putty to ensure a flawless surface;

- 3. Mold Release Agent Application: Evenly spray a dedicated mold release agent (to prevent subsequent silicone adhesion).

Quality Control Points:

Prototype dimensional tolerance ≤±0.1mm, surface free of scratches, air bubbles, dents, and clear details such as markings/threads.

Step 2: Mold Design and Silicone Mold Making

Core Objective:

To create a highly elastic silicone mold with high detail reproduction, suitable for complex structures and reusable.

Mold Frame Construction:

Design the mold frame according to the prototype dimensions, reserving a resin gate (3~8mm diameter) and venting holes (1~2mm diameter). Complex structures use a split mold (2~4 segments).

Silicone Selection and Mixing:

- 1. Silicone Type: Two-component addition-cure silicone (Shore A hardness 10~40, high toughness, low shrinkage);

- 2. Mixing Ratio: Mix at a weight ratio of 1:1 or 10:1, stirring thoroughly (avoiding air bubbles);

- 3. Additives: Thermal conductive agents (to accelerate curing) or tear-resistant agents (to extend mold life) can be added.

Silicone Casting and Curing:

- 1. Slowly pour the silicone to avoid impacting the prototype and causing air bubbles;

- 2. Curing Conditions: Curing at room temperature (25℃) for 4~8 hours, or curing at elevated temperature (60℃). 1~2h;

- 3. Mold disassembly: After curing, cut the mold along the preset parting line and remove the prototype.

Quality control points:

The mold cavity is free of air bubbles and impurities; the edges are neat after disassembly, and the prototype details can be completely restored.

Step 3: Vacuum Degassing

Core Objective:

To eliminate air bubbles in the silicone mold and resin, preventing surface defects in the replica.

Mold Degassing:

Reassemble the disassembled silicone mold, place it in a vacuum chamber, and evacuate to -0.09~-0.1MPa, maintaining this pressure for 15~30 minutes to remove residual air from the cavity.

Resin Degassing:

Prepare the PU resin according to the formula (e.g., hardness, color, additives), stir thoroughly, and place it in a vacuum chamber. Degas for 15~20 minutes using the same parameters.

Quality Control Points:

After degassing, the resin should have no visible air bubbles, and the mold cavity should be free of residual air (observable through a transparent mold frame).

Step 4: Resin Mixing & Pouring

Core Objective:

Precisely adjust resin properties (hardness, color, performance) to completely fill the mold cavity under vacuum.

Resin Selection and Mixing

- 1. Resin Type: Select soft PU (Shore A 30~80), hard PU (Shore D 50~80), transparent PU, flame-retardant PU, etc., according to product requirements;

- 2. Mixing Ratio: Strictly follow the weight ratio in the resin instructions (e.g., 1:1, 2:1), stirring for 3~5 minutes;

- 3. Viscosity Control: Resin viscosity 50~500 mPa・s (room temperature). If the viscosity is too high, heating (≤40℃) is required to reduce it.

Vacuum Pouring

- 1. Slowly inject the degassed resin into the mold gate at a speed of 5~10 ml/s (avoid generating new air bubbles);

- 2. Maintain a vacuum environment (-0.08~-0.1MPa) until the resin completely fills the cavity (this can be confirmed through the mold’s transparent observation window).

Quality control points:

Precise resin ratio, no air bubbles generated during injection, and complete cavity filling (no missing material areas).

Step 5: Curing

Core Objective:

To fully cure the resin in the mold, achieving stable physical properties and dimensional accuracy.

Curing Conditions:

- 1. Room Temperature Curing: Maintain 25℃ for 4~8 hours (suitable for soft PU, avoid high-temperature deformation);

- 2. Heated Curing: Maintain 60~80℃ for 1~2 hours (suitable for rigid PU, improves production efficiency);

- 3. Curing Environment: Keep dry and dust-free, avoid direct sunlight.

Post-Curing Inspection:

Open a corner of the mold, gently touch the product surface, and confirm that it is not sticky or dented before completely demolding.

Quality Control Points:

The product is fully cured (hardness meets standards), with no deformation, no sticking to the mold, and no uneven coloring.

Step 6: Demolding

Core Objective:

To quickly remove the replica without damaging the product or mold.

Demolding Methods:

- 1. Manual Demolding: Suitable for simple structures. Use a plastic pry bar (avoid scratching) to slowly pry open the mold along the parting line.

- 2. Mechanical Demolding: Suitable for complex structures or mass production. Use a dedicated demolding machine (pressure 0.1~0.3MPa).

Mold Maintenance:

After demolding, wipe the mold cavity with alcohol to remove residual resin. Reapply mold release agent for future use.

Quality Control Points:

The product is free of scratches, damage, and mold residue; the mold cavity is intact.

Step 7: Post-Processing

Core Objective:

Optimize product appearance and dimensional accuracy to meet the final delivery requirements of export customers.

Basic Processing

- 1. Remove Gates/Flash: Cut off excess material with scissors, a file, or a grinder, and grind until flush with the product surface.

- 2. Fine Grinding: Grind the surface with 800~2000 grit sandpaper, achieving a roughness Ra≤0.4μm.

Surface Treatment (Optional)

- 1. Spray Painting: Spray primer → topcoat → clear varnish (supports matte, high-gloss, and metallic paints; colors match PANTONE color codes).

- 2. Silk Screen/Pad Printing: Print logos, scales, and text (accuracy ±0.1mm, suitable for brand logos).

- 3. Electroplating/Simulated Anodizing: Provide a metallic texture (e.g., silver, gold, meeting the appearance requirements of export products).

- 4. Assembly: Assemble multiple replica components, ensuring assembly gaps ≤0.1mm.

Quality Control Points:

The product surface is free of scratches, drips, and bubbles; the logo is clear; and assembly precision meets standards.

Step 8: Quality Inspection & Packaging

Core Objective:

Ensure products meet order requirements and adapt to international logistics through compliant packaging.

Quality Inspection:

- 1. Dimensional Inspection: Use calipers, micrometers, or coordinate measuring machines to inspect key dimensions, with tolerances of ±0.1~±0.3mm/100mm;

- 2. Appearance Inspection: Visually inspect surfaces for defects (bubbles, scratches, color differences), with a sampling rate ≥10%;

- 3. Functional Testing: Conduct abrasion resistance, temperature resistance, and impact resistance tests as required by the customer (e.g., abrasion resistance test for tool handle sleeves ≥5000 cycles).

Packaging Methods:

- 1. Single Product: Individually packaged in an anti-static plastic bag lined with bubble wrap (to prevent scratches);

- 2. Bulk Packaging: Placed in export standard cartons, filled with pearl cotton or foam (shockproof and moisture-proof);

- 3. Labeling: Affix product name, quantity, weight, and moisture-proof/fragile label to the outer carton, meeting international logistics requirements.

Quality control points:

Inspection pass rate ≥98%, packaging intact, labeling clear, meeting foreign trade logistics standards.

Suijin Casting Solution

Vacuum casting is a core technology for rapid prototyping and small-batch production in the industrial manufacturing field. Its advantages of short cycle time, high precision, low cost, and diverse materials perfectly suit the R&D iteration of hardware tools/plastic parts and the needs of small-batch foreign trade orders. By rationally selecting materials, optimizing mold design and post-processing, rapid transformation from sample to finished product can be achieved, improving the responsiveness and order competitiveness for foreign trade customers.