In recent years, investment casting has emerged as a key manufacturing process in the automotive industry, enabling the production of high – precision, complex components with enhanced performance and cost – effectiveness. This ancient technique, also known as lost – wax casting, has been revolutionized by modern technology, making it an ideal choice for automotive applications.

Market Growth and Trends

The global automotive investment casting market has been experiencing steady growth, driven by the increasing demand for lightweight, fuel – efficient vehicles. This growth is attributed to several factors, including the adoption of advanced materials, the development of new casting technologies, and the expansion of the automotive industry in emerging economies.

One of the significant trends in the automotive casting market is the growing use of lightweight materials such as aluminum, magnesium, and titanium alloys. These materials offer excellent strength – to – weight ratios, which are crucial for reducing vehicle weight and improving fuel efficiency. Investment casting allows for the precise shaping of these materials, enabling the production of complex components with thin walls and intricate geometries.

Another trend is the increasing demand for electric vehicles (EVs). As the automotive industry shifts towards electrification, investment casting is playing a vital role in the production of EV components such as battery casings, motor housings, and transmission parts. These components require high precision and tight tolerances to ensure optimal performance and safety, making investment casting an ideal manufacturing process.

Applications in the Automotive Industry

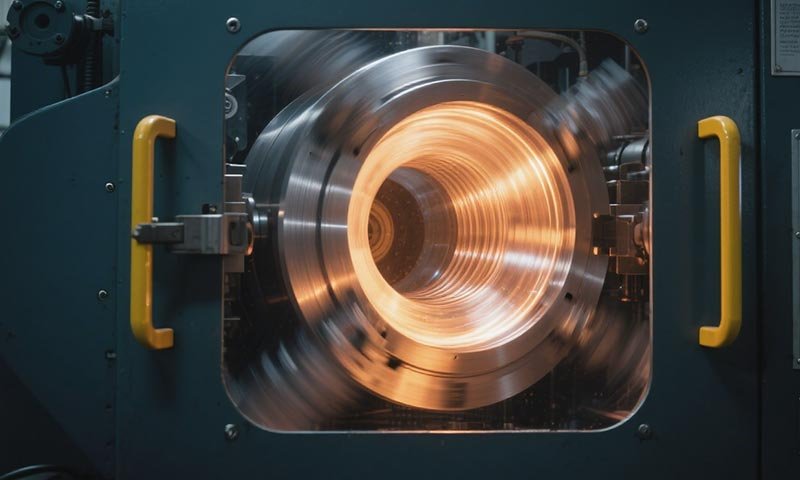

Investment casting is used in a wide range of automotive applications, from engine components to chassis parts. In the engine, investment – cast components such as cylinder heads, pistons, and crankshafts are critical for ensuring efficient combustion and power output. These components are designed to withstand high temperatures, pressures, and mechanical stresses, and investment casting provides the necessary precision and durability to meet these requirements.

In the transmission system, investment – cast gears, shafts, and housings are used to transfer power from the engine to the wheels. These components require high strength and accuracy to ensure smooth operation and minimize power losses. Investment casting allows for the production of complex gear geometries with tight tolerances, resulting in improved transmission efficiency and reduced noise and vibration.

Chassis components such as suspension arms, steering knuckles, and brake calipers are also commonly produced using investment casting. These components need to be lightweight yet strong to enhance vehicle handling and safety. Investment casting enables the creation of intricate designs that optimize the strength – to – weight ratio, resulting in improved performance and fuel efficiency.

Technological Advancements

The investment casting process has undergone significant technological advancements in recent years, further enhancing its capabilities and competitiveness. One of the key developments is the use of computer – aided design (CAD) and computer – aided manufacturing (CAM) technologies. CAD allows designers to create complex 3D models of components, which can then be used to generate precise tooling and casting patterns. CAM systems automate the production process, ensuring consistent quality and high production rates.

Another important advancement is the use of 3D printing in investment casting. 3D printing, also known as additive manufacturing, enables the rapid production of wax or resin patterns with complex geometries. These patterns can be used directly in the investment casting process, eliminating the need for traditional tooling and reducing lead times. 3D printing also allows for greater design flexibility, enabling the creation of components with internal features and hollow structures that are difficult or impossible to produce using traditional manufacturing methods.

In addition, advancements in materials science have led to the development of new alloys and coatings that are specifically designed for investment casting. These materials offer improved mechanical properties, corrosion resistance, and heat resistance, making them suitable for use in demanding automotive applications.

The future of investment casting in the automotive industry looks promising, with continued growth and innovation expected. As the demand for lightweight, fuel – efficient vehicles increases, investment casting will play an increasingly important role in enabling the production of complex, high – performance components. Technological advancements such as 3D printing, CAD/CAM, and advanced materials will further enhance the capabilities of investment casting, making it a more competitive and cost – effective manufacturing process.

In addition, the expansion of the automotive industry in emerging economies, particularly in Asia and Africa, presents significant opportunities for investment casting manufacturers. These regions are experiencing rapid growth in automotive production and consumption, creating a growing demand for high – quality, cost – effective components.

About Suijin Casting