Die Casting Process

Die Casting Introduction

Die casting is a high-precision, high-efficiency metal forming process. Its core principle involves injecting molten metal (such as aluminum alloys or zinc alloys) into a precisely designed mold cavity under high pressure and high speed. After the metal cools and solidifies, the mold is opened to obtain the formed casting.

This process is widely used in the automotive, electronics, home appliance, and industrial equipment industries, and is particularly suitable for the mass production of metal parts with complex structures and high dimensional accuracy requirements.

Die Casting Process

The core of die casting is to achieve mass production of high-precision metal parts through a closed loop of “mold closure → metal melting → high-pressure injection → cooling and solidification → demolding and post-processing”.Based on precision mold forming, high-pressure and high-speed injection is the core, and cooling and post-processing ensure accuracy and performance. The entire process revolves around “batch stability and defect control”.

Suijin Machinery bietet Standard-Prozessabläufe für die industrielle Großserienfertigung und gleichzeitig optimierte Lösungen für die kundenspezifische Fertigung in Kleinserien.

Step 1: Mold Design and Manufacturing

The core of die casting is the mold; this step directly affects casting accuracy, production efficiency, and mold lifespan.

1. Design Stage:

- Inputs: 3D product drawings (tolerances, wall thickness, and surface requirements must be clearly defined), material properties (e.g., aluminum alloy fluidity).

- Design Content: Cavity (replicating product shape), gating system (guiding molten metal for uniform filling), venting system (expelling air from the cavity to prevent porosity), ejection mechanism (ensuring smooth demolding), cooling channels (controlling mold temperature for uniform cooling).

- Key Requirements: Wall thickness ≥ 0.5mm (avoiding incomplete filling), rounded corners (preventing stress concentration), venting groove width 0.1-0.2mm (preventing molten metal overflow).

2. Manufacturing Stage:

- Materials: The mold cavity uses high-strength hot-work die steel (e.g., H13, SKD61), which is heat-resistant and wear-resistant.

- Machining Equipment: CNC machining center (rough machining of cavities), EDM (finish machining of cavities, accuracy up to ±0.005mm), wire cutting (machining of complex structures), polishing (cavity surface Ra≤1.6μm, improving the surface quality of castings).

- Trial Production and Verification: After mold manufacturing is completed, small-batch trial production is conducted to check casting dimensions, surface defects, demolding smoothness, and adjust mold parameters (such as modifying the gating system and optimizing cooling channels).

Step 2: Metal Smelting

Converting raw metal materials into a molten metal liquid with “good fluidity, uniform composition, and no impurities” is the foundation of die casting.

1. Raw Material Preparation:

- Main Materials: Aluminum alloys (ADC12, A380), zinc alloys (ZAMAK 3, ZAMAK 5), magnesium alloys (AZ91D), copper alloys (CuZn38).

- Balancing: Mix pure metal ingots (such as aluminum ingots, zinc ingots), recycled waste castings (≤30%, to avoid impurity accumulation), and alloy additives (such as adding silicon to aluminum alloys to improve fluidity) in a specified proportion.

2. Smelting Process:

- Equipment: “Integrated furnace” (connected to the injection chamber) for hot chamber die casting; “Independent crucible furnace” for cold chamber die casting.

- Temperature Control: Aluminum alloy (melting temperature 680-720℃, holding temperature 650-680℃); Zinc alloy (melting temperature 430-450℃, holding temperature 410-430℃); Magnesium alloy (melting temperature 680-700℃, holding temperature 650-670℃); Copper alloy (melting temperature 950-1000℃, holding temperature 900-950℃).

- Refining Treatment: Add refining agents (such as hexachloroethane for aluminum alloys) to remove gases (hydrogen) and impurities (oxide slag) from the molten metal. Let it stand for 10-20 minutes to ensure the purity of the molten metal.

Step 3: Injection molding

Injecting molten metal into the mold cavity is a crucial step determining the density and precision of the casting. It involves two core methods: hot chamber die casting and cold chamber die casting.

1. Hot Chamber Die Casting

- Hot chamber die casting is a die casting method in which the injection chamber is directly connected to the furnace. Low-melting-point molten metal (such as zinc alloys and some magnesium alloys) is continuously kept at a high temperature in the furnace and rapidly drawn in through the injection rod, then injected into the mold cavity at a pressure of 10-50 MPa.

- It has advantages such as short cycle time (5-15 seconds/piece), high degree of automation, and simple operation, making it suitable for mass production of small, thin-walled, and simple-structured castings (such as appliance parts and toy parts).

2. Cold Chamber Die Casting

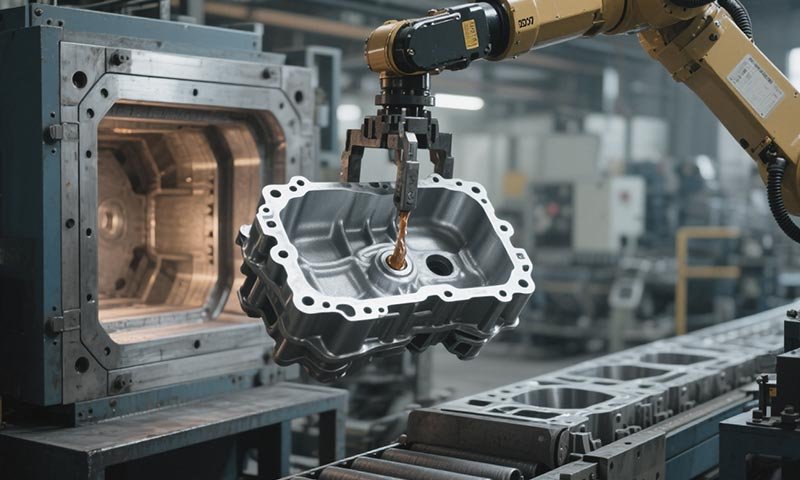

- In cold chamber die casting, the injection chamber is independent of the furnace. High-melting-point molten metal (such as aluminum alloys, copper alloys, and magnesium alloys) needs to be transferred to the injection chamber manually or by a robotic arm. Then, it undergoes segmented injection (slow filling, high-speed injection at 10-50 m/s) and high-pressure forming at 50-150 MPa.

- Although the cycle time is longer (15-60 seconds/piece) and the equipment investment is larger, it is suitable for a wider range of applicable materials, and produces castings with higher strength and dimensional accuracy. It is more suitable for producing large, complex, and high-strength parts (such as automotive engine blocks and industrial equipment brackets).

Step 4: Cooling and Solidification

The molten metal cools and solidifies into a casting within the mold cavity. The cooling rate directly affects the casting’s microstructure and defects (shrinkage cavities, cracks).

- Cooling Method: Cooling water (or heat transfer oil) is circulated through cooling channels within the mold to control the mold temperature within a reasonable range (180-250℃ for aluminum alloy die casting molds, 120-180℃ for zinc alloys).

- Cooling Time: Calculated based on the casting wall thickness. The formula is: Cooling Time (seconds) = Maximum Casting Wall Thickness (mm) × 1.5-2.5 (coefficient, adjusted according to different materials).

- Key Controls: The cooling rate must be uniform, avoiding localized excessively fast cooling (leading to cracks) or excessively slow cooling (leading to shrinkage cavities, porosity). Complex castings require zoned cooling channels, with enhanced cooling for key areas (such as thick-walled sections).

Step 5: Demolding

After cooling, open the mold and remove the casting, avoiding deformation or damage.

- Mold Parting: The mold locking mechanism releases, separating the moving mold from the fixed mold (parting speed 5-10mm/s, avoiding impact).

- Ejecting the Casting: The ejection mechanism (ejector pins, ejector rods) applies even force to eject the casting from the cavity (ejection speed 2-5mm/s, avoiding damage to the casting surface).

- Removal Methods:Hot Chamber Die Casting (Small Parts): Automated removal arm (cycle time 5-15 seconds), high efficiency;Cold Chamber Die Casting (Large Parts): Robotic arm in conjunction with vacuum suction cups or clamps to remove the casting, avoiding deformation caused by manual handling.

Step 6: Post-processing

:Improve casting precision and appearance to meet usage requirements. After demolding, excess material needs to be removed, defects corrected, and the surface optimized.

Step 7: Quality Inspection

Through multi-dimensional inspection, defective products are eliminated to ensure castings meet customer requirements.

- Appearance Inspection: Visual or AI vision inspection to check for surface porosity, cracks, flash, deformation, and other defects.

- Dimensional Inspection: Using calipers, micrometers (for simple dimensions), and coordinate measuring machines (for complex dimensions, accuracy ±0.005mm), a sampling rate of ≥5% (in mass production).

- Internal Defect Inspection: Non-destructive testing: X-ray inspection (to check for internal porosity and shrinkage cavities), ultrasonic testing (to detect cracks), penetrant testing (for surface cracks); Destructive testing: Randomly selected castings are subjected to metallographic analysis (to check microstructure density) and tensile strength testing (to verify mechanical properties).

- Packaging and Shipment: Qualified castings are packaged according to customer requirements (e.g., wrapped in rust-proof paper, boxed in sections), and labeled with batch and quantity for traceability.

Suijin-Gießlösung

Die casting is the optimal forming solution for high-volume, high-precision, and complex non-ferrous metal parts, especially suitable for industries with strict requirements on cost, efficiency, and lightweighting (such as automotive and electronics).