In the modern aerospace industry system, precision machining technology for aircraft parts is hailed as “the pearl on the crown of industry”. From engine turbine blades to landing gear load-bearing structures, from integrated fuselage skins to core interfaces of avionics systems, the manufacturing precision of every key part directly determines the flight safety, overall performance and service life of an aircraft. With the continuous evolution of aviation equipment towards lightweight, high thrust-to-weight ratio and long service life, precision machining technology has become a core competitive barrier in the field of aerospace manufacturing. This paper will systematically analyze the key technical paths, existing industry challenges and future development trends in this field.

The manufacturing of key aircraft components is a highly complex system engineering, and its quality standards have extremely stringent requirements for the safe operation of the entire aircraft. Any precision deviation or performance defect of components may cause system failures and even lead to serious flight accidents. Therefore, precision machining technology has become an indispensable core process in the manufacturing of aircraft parts.

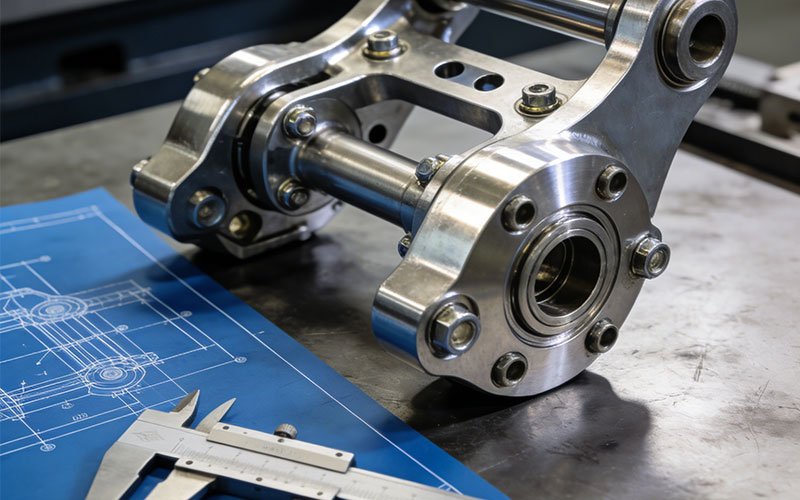

This technology relies on various types of high-end equipment to manufacture aviation components with small tolerance ranges, high dimensional accuracy and excellent surface quality. As a typical subtractive manufacturing process, precision machining achieves the designed size and performance standards of components by accurately removing workpiece materials. Its core equipment includes CNC machine tools, high-precision grinders, honing machines, machining centers, professional deburring equipment and heat treatment equipment.

The precision manufacturing process of aircraft parts is the core cornerstone of the aerospace manufacturing field, and its importance runs through the entire process of aircraft design, production, maintenance and even full life cycle management. From flight safety assurance and continuous performance optimization to industrial economic competition, this technology is not only the “lifeline” of the modern aerospace industry, but also an important symbol to measure a country’s high-end manufacturing strength.

The following will deeply analyze the irreplaceable key roles of precision machining technology for aircraft parts from five dimensions:

1. Safety Assurance: The Core Cornerstone of Aviation Flight

Zero-Defect Manufacturing Requirements

Tiny defects (such as 0.1mm micro-cracks) on key aircraft parts (such as engine blades and landing gear bearings) may cause catastrophic consequences in the extreme working environment of high altitude, high pressure and high temperature. Through micron-level precision control (such as turbine blade tip clearance error ≤ 0.05mm), precision machining technology can reduce the probability of part failure to the level of 10⁻⁹, ensuring that the aircraft has a safe flight cycle of more than 30 years.

Extreme Environment Adaptability

Aerospace components need to withstand huge temperature differences from -55℃ (high-altitude cruise state) to 1500℃ (inside the engine combustion chamber). The precision machining process can ensure the uniformity of the material’s microstructure (such as the crystal orientation error of single-crystal superalloy is less than 3°), thus effectively avoiding part fatigue fracture caused by thermal stress concentration.

2. Performance Improvement: Promoting the Leapfrog Development of Aviation Equipment

Lightweight Technology Revolution

Through technologies such as precision milling (such as 30% weight reduction of titanium alloy integral frames), automated composite material layup (20% weight reduction of Boeing 787 fuselage) and 3D printing topology optimization (25% weight reduction of GE Aviation fuel nozzles), the thrust-to-weight ratio and fuel efficiency of aircraft have been significantly improved. According to estimates, for every ton of weight reduction of the Airbus A350, 700 tons of fuel can be saved annually.

Significant Leap in Aerodynamic Efficiency

The surface roughness of the wing leading edge manufactured by five-axis simultaneous machining technology can reach Ra0.4μm, making the air flow boundary layer more stable and reducing the overall aircraft resistance by 15%; the dimensional accuracy of engine compressor blades is improved to IT4 grade, and the compression efficiency is increased by 8%.

3. Economic Benefits: The Core Grasp of Full Industry Chain Cost Control

Manufacturing Cost Optimization

After precision electrochemical machining (PECM) replaces the traditional EDM process, the processing efficiency of Inconel 718 alloy fuel nozzles is increased by 5 times, and the unit cost is reduced by 40%; high-speed milling technology can shorten the processing cycle of titanium alloy parts by 60%.

Maintenance Cost Innovation

Additive manufacturing repair technology (such as laser cladding) can reduce the maintenance cost of engine blades to 20% of that of new parts and extend the service life of parts by 3 times. Pratt & Whitney saves more than 1.2 billion US dollars in maintenance costs every year through digital remanufacturing technology.

4. Technical Barriers: The “Moat” of National High-End Manufacturing Industry

Material-Process Collaborative Breakthrough

At present, only 5 countries in the world have mastered the supporting processing technology of superalloys (such as CMSX-4) and superhard tools (PCD/PCBN); the positioning accuracy (±0.1mm) and laying speed (1m/s) of automatic composite material filament winding machines constitute the core technical barriers in this field.

Independent Controllability of Core Equipment

The key technologies of RTCP (Rotation Tool Center Point) algorithm of five-axis simultaneous CNC machine tools and online measurement systems have long been monopolized by European and American countries. The independently developed S-shaped test piece detection standard in China has successfully broken the technical blockade of the West in the field of five-axis machine tool accuracy certification.

5. Strategic Value: The High Ground of Future Aviation Competition

Sixth-Generation Fighter Jets and New Energy Aircraft

Adaptive cycle engines require precision connection technology of 2000℃ high-temperature resistant ceramic matrix composites (CMC); the carbon fiber winding accuracy requirement of hydrogen aircraft hydrogen storage tanks reaches 0.01mm level, which directly determines its commercial feasibility.

Space Economy and Hypersonic Flight

The micro-hole machining technology (aperture tolerance ±0.005mm) of C/C composite materials for spacecraft thermal protection systems (TPS) and the manufacturing of active cooling channels at the leading edge of hypersonic vehicles are highly dependent on ultra-precision machining capabilities.

Precision machining technology for aircraft components is the product of the deep integration of materials science, mechanical engineering and information technology. With the development of aviation equipment towards the sixth-generation intelligent direction, the machining accuracy will jump from micron level to submicron level, and the process chain will also evolve towards full digitalization and networking. In this core field related to national strategic competitiveness, only continuous technological innovation can support the eternal dream of human beings flying in the blue sky.

If you would like to learn more about precision machining technology for aircraft components, please feel free to contact us.