Investment casting involves numerous repetitive and complex processes. Leveraging robotics to execute these steps delivers substantial benefits to customers. The integration of robotics in investment casting (lost-wax casting) is gradually revolutionizing traditional workflows, enhancing production efficiency and casting quality through automation and precision operations.

Below is a detailed analysis of its core applications, advantages, and typical use cases:

I. Core Applications of Robotics in Investment Casting

1. Wax Pattern Fabrication and Assembly

Wax Injection Molding

Robots equipped with high-precision robotic arms control the injection pressure, temperature, and time of wax patterns, enabling rapid prototyping of complex wax molds—such as those for aircraft engine blades and precision medical components. Advantage: Compared with manual injection, dimensional tolerance is controlled within ±0.02mm, effectively reducing air bubbles and shrinkage cavities.

Wax Pattern Assembly (Wax Tree Construction)

Using visual recognition systems, robots locate wax patterns and automatically weld or bond individual patterns into wax trees (modules), replacing manual piece-by-piece assembly. Case Study: For wax tree assembly of automotive turbocharger impellers, robots can accurately position and weld over 20 wax patterns in 5 minutes, tripling efficiency.

2. Shell Preparation (Coating and Grinding)

Automated Shell Coating Production Line

Robots grasp wax trees and dip them into coating tanks. Multi-axis motion control ensures uniform coating adhesion, making it particularly suitable for complex structures such as deep holes (length-to-diameter ratio >5:1) and narrow gaps (e.g., internal cavity coating of aerospace castings).Data: The thickness tolerance of each coating layer in traditional manual operations is approximately ±15%, while robotic shell coating reduces this tolerance to within ±5%.

Intelligent Grinding System

Based on the shell’s position, robots dynamically adjust grinding angles and pressure to prevent sand accumulation or leakage, reducing “shell defects” such as sand holes and shell peeling.

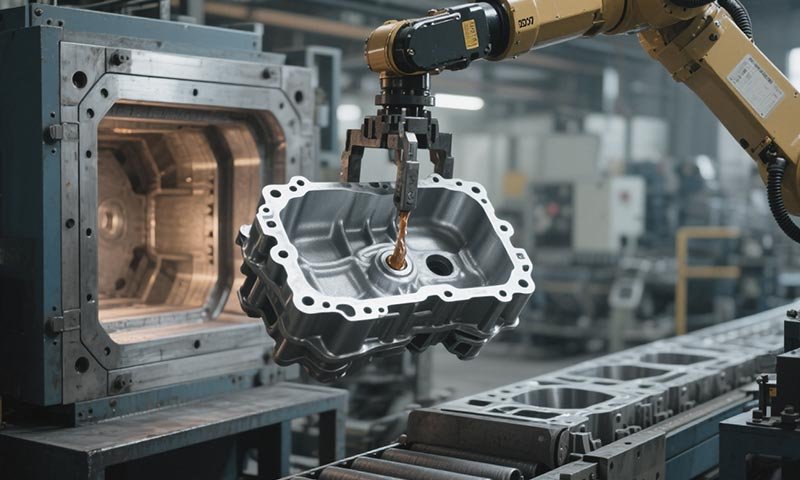

3. Dewaxing and Shell Processing

High-Temperature Dewaxing Operation

Robots move wax tree frames into dewaxing kettles under high-temperature environments (80-120℃), avoiding manual contact with steam and molten wax to improve safety. Some robots are equipped with non-stick coated robotic arms to minimize wax residue.

Shell Drying and Inspection

Robots are fitted with infrared sensors to real-time monitor shell drying levels and automatically adjust air flow and temperature in drying furnaces; visual inspection systems scan the shell surface to identify defects such as cracks and uneven thickness.

4. Metal Pouring and Cooling Control

Precision Pouring Robots

These robots connect smelting furnaces and ladles, using force-controlled sensors to precisely regulate pouring speed (e.g., adjustable within the range of 0.1-5 kg/s), avoiding turbulence and splashing, and reducing defects such as incomplete pouring and cold shuts. Application: In superalloy castings for aircraft engines, robotic pouring reduces the rejection rate from 12% (manual operation) to below 5%.

Cooling Path Planning

According to the casting’s material and structure, robots place the shell in the optimal position at the cooling station (e.g., near air-cooled nozzles or slow cooling zones), optimizing the cooling gradient and reducing thermal stress deformation.

5. Casting Cleaning and Post-Processing

Automated Shell Removal and Grinding

Robots use high-pressure water jets or sandblasting tools to remove casting shells, and leverage force-controlled robotic arms to grind burrs (e.g., blade burrs and internal cavity burrs), avoiding dimensional deviations caused by manual operations. Efficiency Comparison: Manual cleaning of a single aerospace casting takes 2-3 hours, while robots complete the task in only 40 minutes, reducing the surface roughness Ra value from 12.5μm to 3.2μm.

Defect Repair (3D Printing Repair Welding)

Some high-end robots integrate laser cladding functions, enabling 3D printing repair of local casting defects (e.g., air holes and shrinkage cavities) to replace traditional argon arc welding repair, thereby reducing deformation in the heat-affected zone.

II. Core Advantages of Robotics Technology

1. Higher Precision and Consistency

Micron-Level Control Capability

In wax pattern assembly and shell coating processes, robots achieve a repeat positioning accuracy of ±0.05mm, ensuring each investment casting’s dimensional tolerance is controlled within ±0.1%. This meets the high-precision requirements of aerospace, medical, and other critical industries.

Standardization of Process Parameters

Robots operate strictly according to preset programs (e.g., coating viscosity, grinding time, pouring speed), replacing manual empirical operations. This eliminates human-induced fluctuations, increasing the qualification rate of mass production by 20-30%.

2. Significant Improvement in Production Efficiency

24/7 Continuous Operation

Robots require no rest and can realize three-shift production, boosting unit capacity by over 50%. For example, an automotive component manufacturer increased monthly output from 8,000 units to 12,000 units after introducing shell coating robots.

Seamless Process Connection

Robotic assembly lines integrate wax pattern preparation, shell coating, pouring, and other processes, significantly shortening workpiece turnover time. Traditional manual operations take 15-30 minutes per process, while robotic operations require only 2-5 minutes.

3. Capability to Manufacture Complex-Structure Castings

Breaking Through Traditional Process Bottlenecks. For investment castings with deep holes (length-to-diameter ratio >5:1), thin walls (wall thickness <1mm), or complex internal cavities, robots achieve precise wax pattern molding and uniform shell coating through multi-axis linkage—tasks that are extremely challenging for manual operations. Case: After robotic shell coating, the qualification rate of gas turbine blades (0.8mm wall thickness with complex internal cavities) increased from 35% to 78%.

4. Enhanced Safety and Environmental Friendliness

Replacing Humans in Hazardous Environments

In high-temperature (>1000℃) and high-dust environments (e.g., dewaxing and pouring), robots eliminate risks such as burns and silica dust inhalation for workers, complying with occupational health and safety standards.

Reducing Material Waste

Precise control of shell coating and pouring reduces consumption of coatings, sand, and molten metal (e.g., coating utilization rate increased from 60% in manual operations to 85%). It also minimizes waste generation and carbon emissions.

5. Smart Production and Data-Driven Operations

Integration with Industrial Internet of Things (IIoT)

Robots collect real-time process data (e.g., wax pattern temperature, coating viscosity, pouring pressure) via sensors and upload it to Manufacturing Execution Systems (MES) for analysis. This enables dynamic optimization of process parameters (e.g., adjusting coating layers based on real-time data).

Predictive Maintenance

By analyzing robotic operation data (e.g., robotic arm joint wear, motor current fluctuations), early warnings for equipment failures can be issued. This reduces downtime—extending maintenance cycles by 30% and lowering failure rates by 40%.

Introduction to Suijin Investment Casting Manufacturers:

As a precision investment casting manufacturer, Ningbo Suijin Machinery Technology Co., Ltd. focuses on producing high-precision, complex-shaped investment castings for critical industries such as aerospace, automotive, medical devices, and energy. Equipped with advanced robotic systems and intelligent production lines, we automate the entire process from wax pattern making to post-processing, ensuring superior product quality, high production efficiency, and consistent batch performance. Adhering strictly to quality management systems and environmental standards, we provide customized investment casting solutions to meet the diverse technical needs of our global clients, driving technological innovation and industrial upgrading in the precision investment casting industry.