Casting Process

1. Sand Casting

The most traditional and widely used process. A mold is created using sand (often silica sand) mixed with a binder to hold its shape. Molten metal is poured into the sand mold cavity, which is formed by compacting sand around a pattern (a replica of the part). Once the metal solidifies, the sand mold is broken to retrieve the casting.

Subtypes: Green sand casting (uses moist sand), dry sand casting (dried sand mold), and resin-bonded sand casting (uses synthetic resins for higher precision).

2. Investment Casting (Lost-Wax Casting)

A precision process ideal for complex, high-detail parts. A wax pattern (or wax-like material) is created, coated with multiple layers of ceramic slurry to form a hard shell. The wax is melted and removed (hence “lost-wax”), leaving a hollow ceramic mold. Molten metal is poured into the mold, and the ceramic shell is shattered after solidification.

Key advantage: Produces parts with tight tolerances and smooth surfaces, suitable for intricate geometries (e.g., turbine blades).

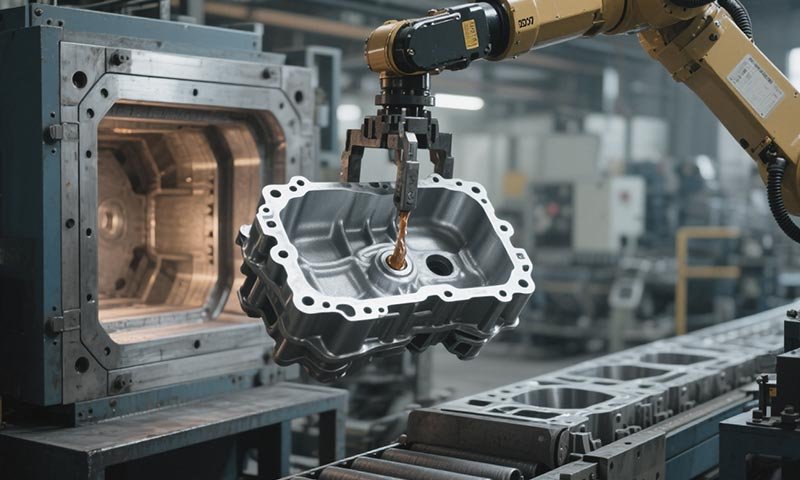

3. Die Casting

Involves forcing molten metal (typically non-ferrous metals like aluminum, zinc, or magnesium) into a reusable metal die (usually made of steel) under high pressure. The die has cavities that replicate the part’s shape, allowing rapid production of high-volume, complex components.

Subtypes: Hot-chamber die casting (for low-melting-point metals like zinc) and cold-chamber die casting (for higher-melting-point metals like aluminum).

4. Permanent Mold Casting

Uses a reusable, rigid mold (often made of cast iron or steel) instead of sand. Molten metal is poured or gravity-fed into the mold, which is preheated to prevent thermal shock. Once solidified, the mold is opened to remove the casting.

Advantage: Better surface finish and dimensional accuracy than sand casting, suitable for medium-volume production (e.g., automotive parts).

5. Centrifugal Casting

Relies on centrifugal force to distribute molten metal. The mold is rotated at high speed while molten metal is poured into it; the force pushes the metal against the mold wall, creating a dense, uniform casting.

Typical applications: Cylindrical parts like pipes, tubes, and sleeves.

6. Continuous Casting

A process for producing long, uniform shapes (e.g., rods, bars, sheets, or slabs). Molten metal is poured into an open-ended, water-cooled mold, where it solidifies partially as it is continuously pulled out. The solidified part is cut to desired lengths.

Used in: Steel, aluminum, and copper production for efficient, high-volume manufacturing.

7. Gravity Die Casting

A variation of permanent mold casting where molten metal fills the mold cavity solely by gravity (no external pressure). It balances cost and precision, suitable for parts with moderate complexity.

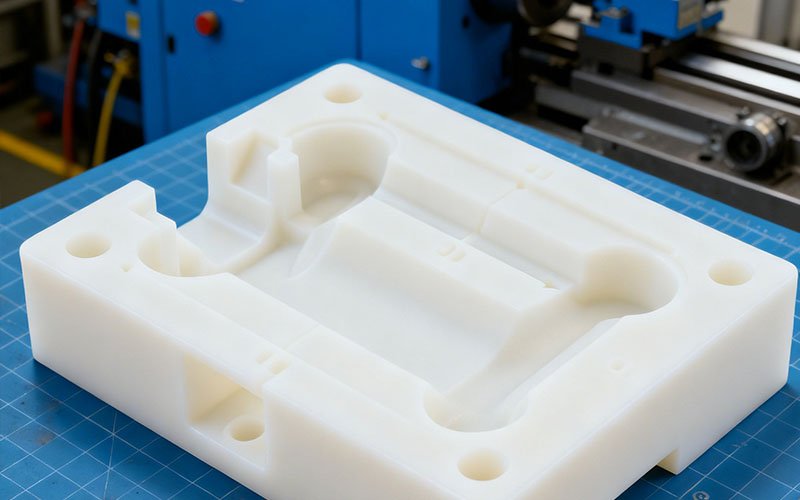

8. Vacuum Casting

Molten metal is poured into a mold under vacuum to minimize porosity and ensure complete filling of complex cavities. Commonly used for high-integrity parts in aerospace or medical industries.

Each process offers unique advantages in terms of cost, production volume, part complexity, and material compatibility, making them suitable for different industrial applications.