SJ Machinery

One-Step Service For Casting And Machining Solution – Since 2003 !

Casting Services

Provide most cost competitive and quality priority casting parts solution to our customer and to maximise our positive impact on casting and CNC machining technology revolution.

Sand Casting

Green sand casting (uses moist sand), dry sand casting (dried sand mold), and resin-bonded sand casting (uses synthetic resins for higher precision).

Investment Casting (Lost-Wax Casting)

Ideal for complex, high-detail parts.Produces parts with tight tolerances and smooth surfaces, suitable for intricate geometries

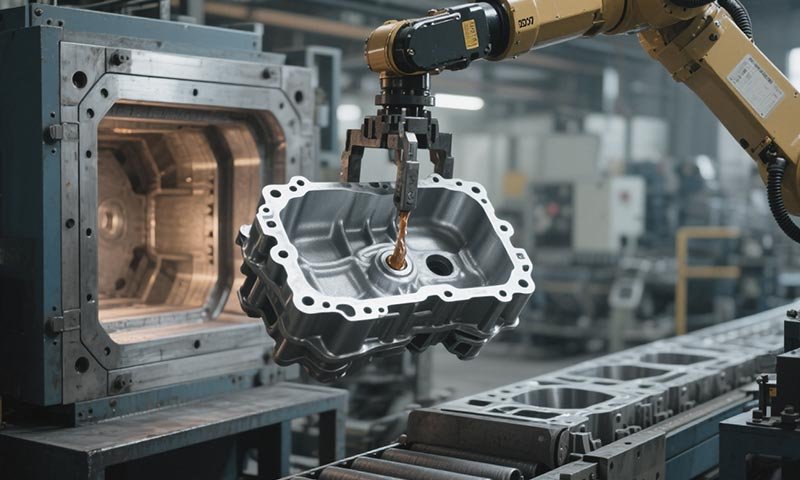

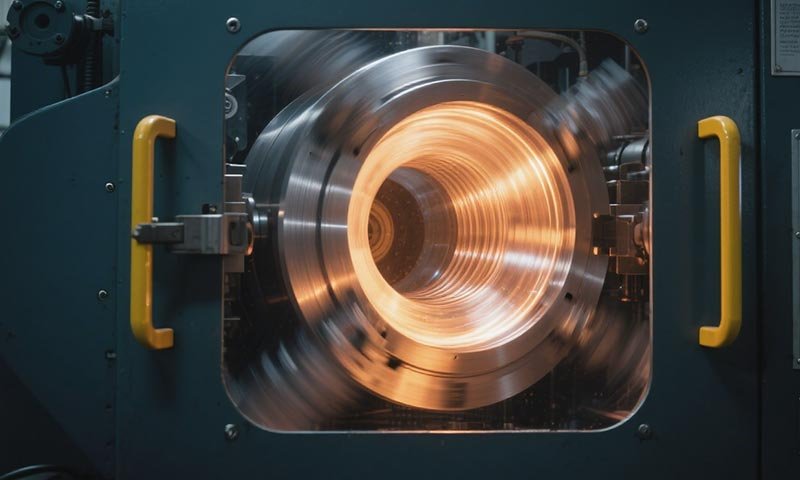

Centrifugal Casting

The mold is rotated at high speed while molten metal is poured into it; the force pushes the metal against the mold wall, creating a dense, uniform casting.

Gravity Die Casting

Molten metal fills the mold cavity solely by gravity (no external pressure). It balances cost and precision, suitable for parts with moderate complexity.

About Suijin Machinery

Ningbo Suijin Machinery Technology Co., Ltd is located in Ningbo city, Zhejiang Province.

We are specialized in manufacturing wide range of investment castings and machining parts. The part including various materials such as carbon steel, alloy steel, and stainless steel and so on.

We understand that different industries have varying requirements for casting performance, materials, and structures. Therefore, we have established a comprehensive customization system, from needs analysis to finished product delivery. Whether it’s high-temperature alloy parts for aerospace, high-precision implants for medical devices, or complex structural components for industrial machinery, we can design a customized casting solution based on customer drawings, performance parameters, and even conceptual ideas. From wax pattern formulation adjustment and shell material selection to pouring process optimization, we ensure that each product is precisely tailored to the customer’s specific needs.

Employees

Years in Business

Casting Process

CORE ADVANTAGE

There list the core advantage of our comtapy in the market.

%

100% control in parts quality

Our company has 100% control in thread checking, leakage test, high requirement tolerance checking with air gauge or position gauge, corrosion resistant for the related material and so on.

01

Performance in customer communication, after-sales service and customer

satisfaction, including customized services and rapid response capabilities.

02

Capabilities in product research and development, process improvement and

technological innovation, including the speed of new product development.

03

Has Strength in quality management and quality control, including the standards

followed, quality assurance system and product quality stability.

04

Has advantages in production equipment, technology and human resources,

including production efficiency, capacity and flexibility.

News

Learn more about suijin and castings

2026 Chinese Spring Festival Holiday Notice

Happy Spring Festival 2026 ! Dear Esteemed Global Clients and Partners, As the 2026 Spring Festival, the most important traditional festival in China (Year of the Horse), draws near, we would like to extend our warmest greetings and sincere thanks to you for your...

3D Printing Investment Casting Technology Innovation

The integration of 3D Printing Investment Casting technology has revolutionized this time-honored process, driving unprecedented innovations that are redefining the boundaries of precision manufacturing, enhancing efficiency, and unlocking new possibilities...

Metal Prototype Casting Process: Principles, Steps, and Applications

In the field of manufacturing, metal prototype casting serves as critical bridges between design concepts and mass production. They enable engineers and designers to validate form, fit, and function, identify potential flaws, and optimize product performance...